The Centre for Future Clean Mobility partners with businesses to develop low-emissions, high-efficiency integrated power systems for applications in the aerospace, automotive, marine, and rail sectors.

The initial collaboration between Centre for Future Clean Mobility (CFCM) & Lynch Motors began through the ERDF funded Marine Business Technology Centre (MBTC) project that enabled CFCM to provide business support & innovation expertise to Lynch Motors. This laid the foundation to develop this collaboration into a Knowledge Transfer Partnership (KTP) project. The pioneering work of this partnership was recognised and awarded the ‘Innovation Award’ by the MBTC board.

Professor Chris Smith, CFCM Director and KTP, Richard Creek, worked closely with Lynch Motors to find a way to explore alternatives to diesel-engines for small boat owners.

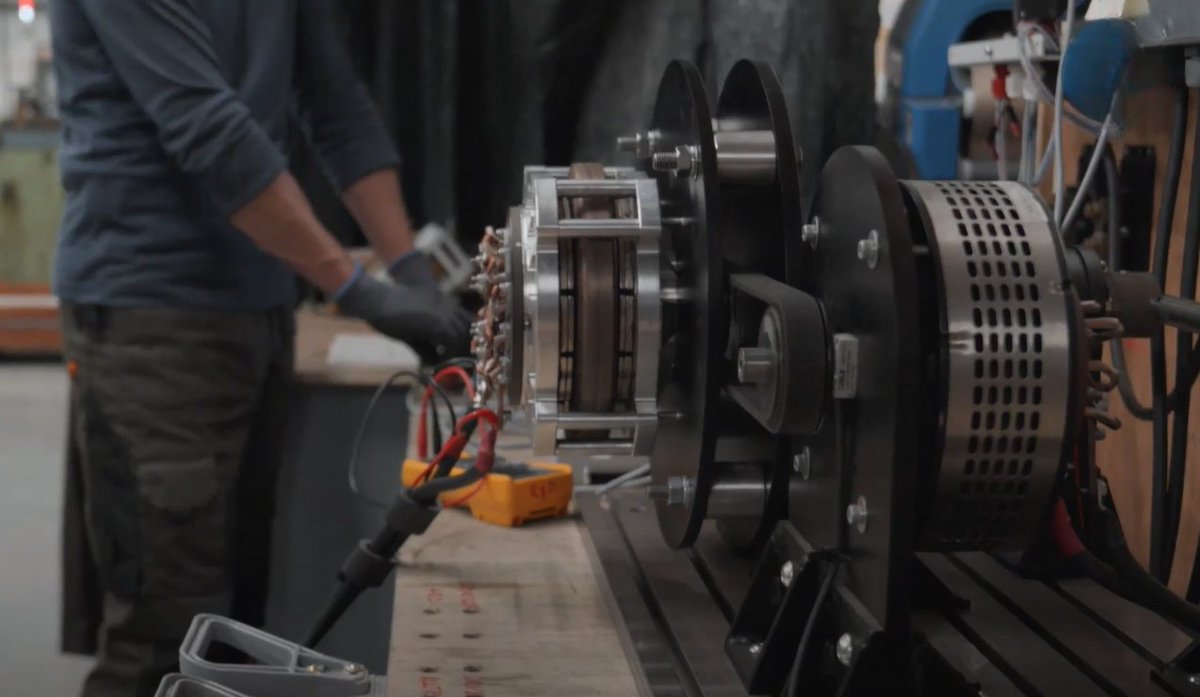

In this project, the primary objective was to develop a larger electric motor that would be highly efficient, powerful, and cost-effective compared to other motors available in the market. The development process utilized simulation-driven design techniques to create a new 12-pole electric motor design, increasing the power output of the Lynch Motor range by 50%. Upon project completion, the first prototype underwent prompt testing. This new motor holds the potential to expand Lynch Motors’ market opportunities, particularly in larger vessels, with a specific focus on electric-only propulsion.

Additionally, the project explored the design of a new diesel-electric parallel hybrid assembly, incorporating an electromagnetic clutch. To utilize existing Lynch motors as generators, a modified motor controller was required. After establishing a successful partnership with a UK supplier, the necessary modified controller was sourced.

Furthermore, the project entailed the development of a programmable battery management solution, enabling control over clutch engagement in various hybrid modes: diesel drive, electric motor drive, or diesel-to-electric generator. This solution provides an additional means to recharge the battery supply.

CFCM provided valuable support to Lynch Motors in proactively addressing potential engineering challenges and development costs. In addition to meeting performance requirements, the new motor design placed emphasis on optimising component geometry to reduce raw material usage and ensure cost-effective machining. Simultaneously, Lynch Motors expanded their in-house manufacturing capabilities, countering industry-wide supply chain disruptions caused by Brexit & Covid-19.

Lynch Motors have hired Knowledge Transfer Partnership (KTP) Associate, Richard Creek as a full-time employee for the final stages of prototype assembly and field trials testing as they go on to lead in a new, greener, market. The KTP was rated ‘Very Good’ by Innovate UK.

The Centre for Future Clean Mobility partners with businesses to develop low-emissions, high-efficiency integrated power systems for applications in the marine, off-highway, rail, defence, and energy sectors.

Website by NOSY Creative Agency